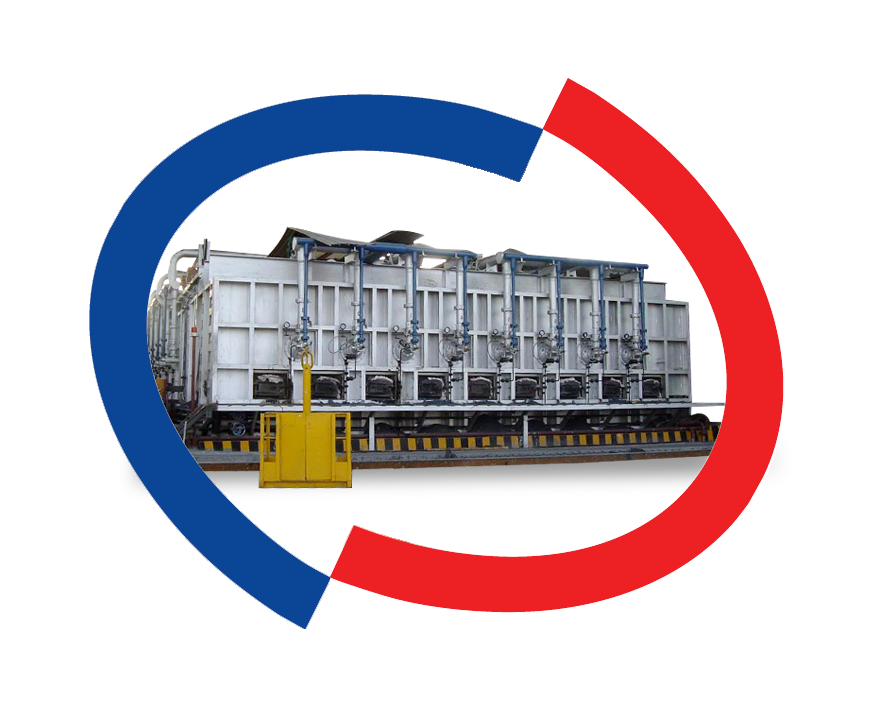

Reheating Furnaces

Our Reheating Furnaces Ensure:

Reheating furnaces are used in hot rolling mills for heating steel stock (Billets) to rolling temperatures, to make it suitable for deformation, which can be further rolled in the steel mill. The function of a reheating furnace is to heat steel stock or billets to rolling temperature to prepare the semi-finished product, i.e., the billet cast for the next stage of rolling by the continuous casting machine.

Our Reheating Furnaces Ensure:

Reheating Furnaces from The Steefo Group takes billets to the correct thermal level. It guarantees good thermal homogeneity as we understand that the quality of the rolling process of the finished product depends precisely on this aspect.

The Steefo Group’s Reheating Furnace is carefully designed to limit the presence of marks on the semi-finished material. These marks, also known as skid marks, can have consequences on the surface quality of the final rolled product, often leading it to be discarded. We use supports called riders of high metallurgical quality to eliminate these marks, produced in nickel superalloys that prevent oxides’ presence.

Our Reheating Furnaces are created keeping in mind the importance of combustion automation. We guarantee a good level of combustion automation due to the modulation in the frequency of the flames, ensuring both complete combustions and a low level of Nitrogen Oxide (NOx) production. This also reduces the environmental impact of reheating a billet, and the complex furnace design ensures high energy efficiency.

The Steefo Group knows how important high energy efficiency is to you; that is why we use high-quality refractory materials to ensure the seamless functioning and stability of the furnace. This also shortens furnace outages when stopped for maintenance. We promote energy efficiency by providing quality insulation for the furnace that reheats the billets.

The Steefo Group Guarantee:

The Steefo Group has been a reliable provider of the best-in-class and highly efficient billet reheating furnaces for the hot rolling mill industry. We provide our customers with a simple, cost-effective way of optimising reheating furnaces for heat treatment. With The Steefo Group Guarantee, enjoy robust design, higher productivity and lower consumption rates.

A reheating furnace constitutes the first step of stock after delivery from the stock yard. Before hot rolling, the blooms/ slabs/ billets must be heated at certain temperatures. Steel stock billets are heated up to a temperature of 1150 degrees Celsius. In this process, billets are charged into the reheating furnace, whereby they are heated to rolling temperatures.

Our Product Range