Shears

Steefo manufactures multiple types of high-performance shears.

Shearing machines are multipurpose devices used in the cutting of steel.

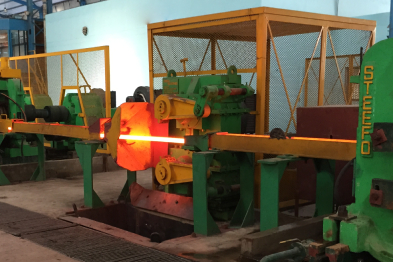

A Shearing machine is an integral part of a hot rolling mill, installed for cutting front/tail end, cobbling, length cutting for cooling bed and commercial length cutting for TMT Bar. Steefo Industries manufactures a range of high-quality and performance-driven shears for steel plants.

Flying Dividing Shear: To cut TMT Bar as per Cooling Bed Length. Our Fly shears can cut up to a finishing speed of 20 mps.

Continuous Shear: To cut TMT Bar as per Cooling Bed Length at higher finishing speeds.

End Cutting Crop and Cobble Shear: These shears are used to cut the front end and tail end and for segment cutting in case of eventualities in hot rolling. They are controlled through a PLC system and give very near tolerance to the cropped length. They are start/stop type and driven using either a Direct DC motor or Flywheel mounted Pneumatic Clutch/Brake.

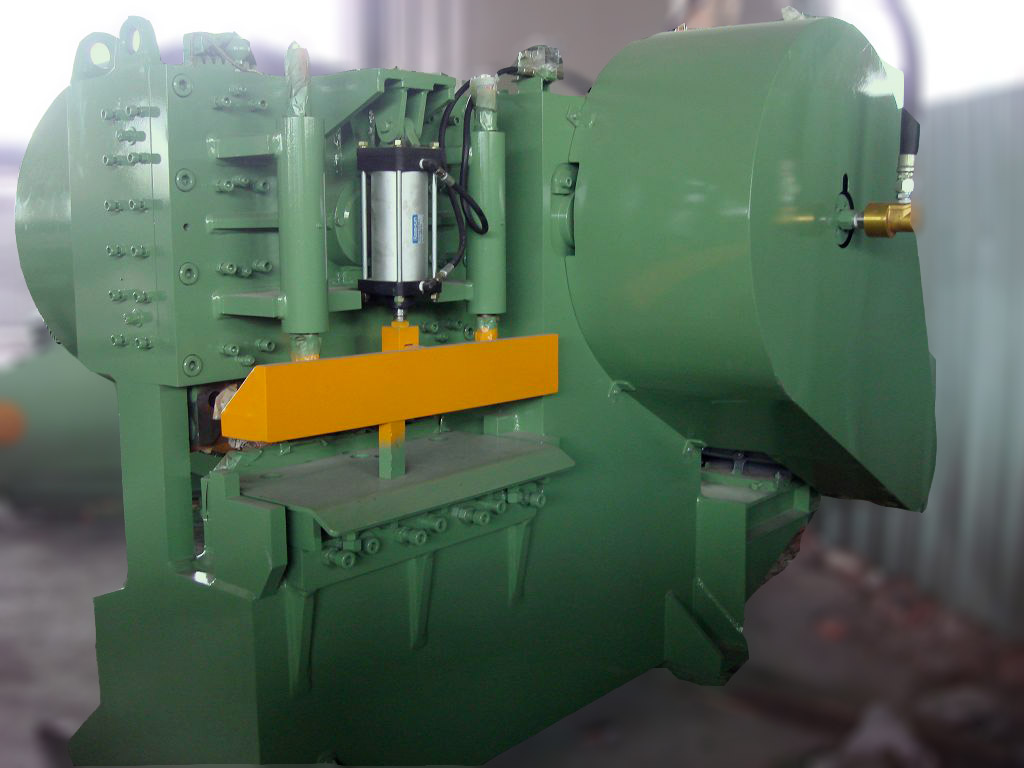

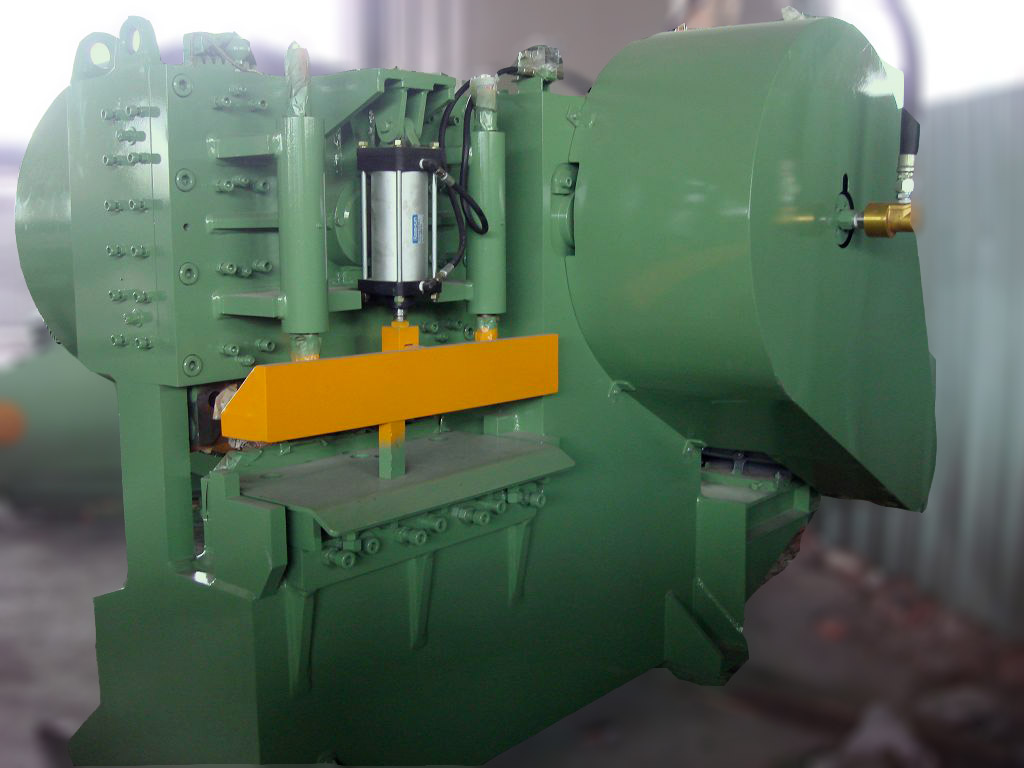

- Pneumatic Clutch Brake Type Cold Shear

- Hydraulic Cold Shear

- Electro-Mechanical Cold Shear