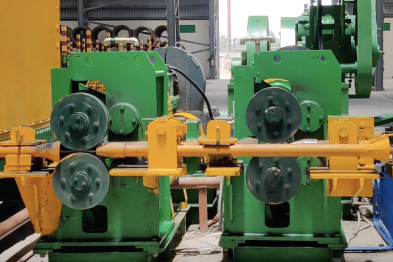

Pinch Rollers

What is a Pinch Roller?

A Pinch Roller is an essential component or product when working with hot rolling and is used extensively throughout the hot strip steel mills. They operate on a horizontal cantilever structure with a double roll device and an air cylinder, allowing it to control the up and down roll synchronous clamp. Pinch Rollers come with an innate lubrication property and have a particular resistance to the bonding of dissimilar metals. It also aids in eradicating coil rejection because of inferior surface quality. The metallurgical characteristics of the rolls assist in supplying resistance to the adhesive and the abrasive wear. This then supports expanding the length and giving uniform wear to each campaign pinch roll utilized in the process.

Overall, pinch rollers are engineered to deliver optimum performance and can meet up with the needs of the hot steel strip coiling application.

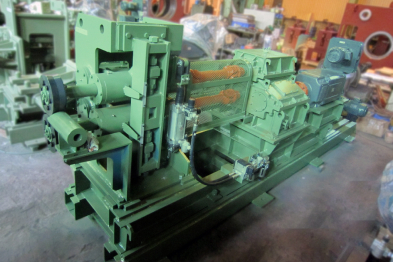

Tail Breakers

Tail Breakers are set up before the cooling bed and after the flying shear to reduce the velocity of TMT bars. It works with AC and DC variable drives, and the pneumatic cylinder separates them. The Steefo Group produces Tail breakers created with the most high-quality raw material and technology. They are also available at an economical price considering their superior performance and durability.

High-Speed Pinch Roller

High-Speed Pinch Roller is operated at a separate location in the rolling mill before and after the TMT quenching box to provide constant tension to the bar. It is also designed with a spherical roller bearing. High-speed pinch rollers provided by The Steefo group have a wear-resistant surface along with anti-friction mounting support.

Our Product Range