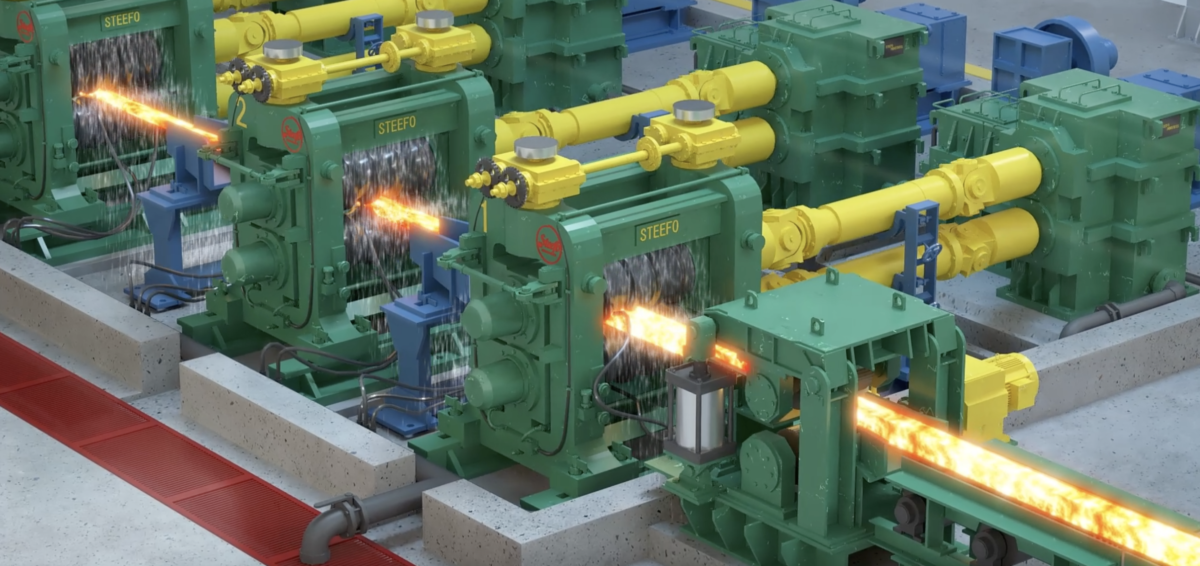

Rolls are fundamental rolling mill machinery of the rolling process, which is integral to the production of various steel products. These rolls, often subjected to extreme conditions, directly influence the quality, throughput, and longevity of the entire rolling mill. They play a critical role in controlling material thickness, shape, and surface finish, making them essential to ensuring that the desired output is achieved. Properly maintained rolls are vital for operational efficiency and product quality.

In a steel rolling mill, rolls endure substantial wear and tear from high pressures, heat fluctuations, and continuous contact with metal surfaces. The constant forces placed on them mean that, without regular maintenance and timely inspections, rolls can experience premature failure, resulting in increased downtime, repair costs, and diminished product quality.

This post provides actionable tips and strategies for maintaining rolling mill rolls, focusing on key aspects such as inspections, lubrication, and predictive maintenance. By following these best practices, you can significantly extend the life of your rolls, reduce operational costs, and ensure smooth and efficient mill operation.

Rolling Mill Rolls: The Heart of the Rolling Process

In any rolling mill, the rolls are critical in shaping and forming steel products. They apply the necessary pressure to flatten or shape materials as they pass between the rollers. Rolling mill rolls help control the material thickness, the surface finish of the metal, and its shape, which are crucial for producing high-quality products. Without proper functioning rolls, the final product will not meet the required standards for tolerance and finish.

While various types of rolls exist depending on the rolling process, the core function remains the same: to apply uniform pressure to the metal, shaping it as it moves through the mill. The rolls need to be precisely designed and built to withstand the immense forces exerted on them during operation.

Challenges Rolls Face During Operation

Rolling mill rolls face numerous challenges throughout their operational life. These challenges arise from high pressure, temperature changes, friction, and repeated loading, all of which contribute to wear and tear on the rolls.

High Pressure

As metal is compressed between the rolls, it endures extreme pressure that can lead to gradual wear. Over time, this constant pressure causes the surface to deteriorate, affecting the roll’s performance. The material becomes harder to shape, and the rolls can start to develop indentations, which impact product quality.

Temperature Fluctuations

During rolling, temperature variations can cause thermal stresses on the rolls. The high heat generated during operations can lead to the expansion of the roll material, while cooling cycles can cause it to contract. These fluctuations can result in cracks, distortion, and a weakened roll structure, reducing its lifespan.

Constant Contact with Metal

The rolls are in continuous contact with the metal being processed, leading to friction and surface wear. This constant interaction accelerates material degradation, causing grooves and pitting on the roll surface. Over time, this friction reduces the effectiveness of this rolling mill machinery, requiring more frequent maintenance.

Stress from Repeated Loading and Unloading

Each cycle of the rolling process adds stress to the rolls. Repeated loading and unloading cause fatigue, which can lead to cracks and other forms of damage. This cyclic stress weakens the roll over time, contributing to premature wear and reduced efficiency in the rolling mill.

Why Rolls Fail Prematurely

Premature roll failure can be costly and disrupt the operations of a rolling mill. Several factors contribute to this, from thermal and mechanical stresses to environmental exposure. Understanding these factors can help mitigate damage and extend the life of the rolls.

Cracking

Cracking is one of the most common causes of premature roll failure. It often occurs due to the combination of thermal and mechanical stresses, which create pressure on the roll’s surface. Uneven cooling after high-temperature operations can exacerbate these stresses, leading to the formation of cracks. These cracks not only compromise the structural integrity of the roll but also affect the consistency and quality of the rolled product, making it essential to detect them early to prevent catastrophic failure.

Corrosion

Exposure to chemicals, moisture, or humidity can lead to corrosion on the surface of the rolls. Corrosion weakens the roll material, leading to pitting, rust, and surface degradation. The corrosive elements can seep into the metal, causing microscopic fractures that eventually lead to more severe damage. In rolling mills, where rolling mill machinery is exposed to high temperatures and various chemicals, preventing corrosion through proper maintenance and material selection is critical to ensure rolls perform efficiently over time.

Abrasion

The constant friction between the rolls and the metal being processed leads to abrasion, which wears down the roll surface. Over time, this abrasion causes grooves, pits, and uneven wear, affecting the roll’s ability to apply consistent pressure. As the roll surface deteriorates, the overall quality of the product also suffers. Regular maintenance, such as resurfacing and lubrication, can help mitigate excessive abrasion and prolong the life of the rolls.

Thermal Fatigue

Thermal fatigue occurs when the rolls experience repeated cycles of high-temperature exposure followed by cooling. These temperature fluctuations cause the roll material to expand and contract, which, over time, leads to internal stress and cracking. This is particularly problematic in high-speed rolling operations where temperature changes are more rapid and frequent. Thermal fatigue weakens the rolls, making them prone to premature failure, especially in the absence of effective cooling and temperature management systems.

Premature roll failure not only increases maintenance costs but can also compromise the quality of the product and cause unplanned downtime. Understanding the challenges and the causes of this part of rolling mill machinery failure is the first step in maintaining the longevity of the rolls.

Best Practices for Extending the Life of Rolling Mill Rolls

Visual Inspections:

Routine visual checks are essential for identifying cracks, pitting, and surface damage before they escalate into more serious issues. Visual inspections should be performed by experienced operators who can spot early signs of wear. Look for signs such as surface cracks, wear patterns, or discolouration that may suggest the onset of fatigue.

Microscopic Inspection:

For early-stage defects like microcracks or stress points that are not visible to the naked eye, microscopic inspection techniques can be highly beneficial. This ensures that small issues are caught before they lead to larger cracks or roll failure.

Non-Destructive Testing (NDT):

Non-destructive testing techniques, such as ultrasonic testing or eddy current testing, are effective tools for detecting internal damage that is invisible on the surface. These methods allow for the identification of issues like cracks beneath the surface or other structural weaknesses without compromising the roll.

Inspection Frequency:

The frequency of inspections should be based on rolling conditions, the material being processed, and the roll material itself. In general, it is advisable to inspect the rolling mill machinery regularly, particularly when running heavy-duty operations or using high temperatures, as these factors increase wear.

Lubrication and Cooling: Preventing Overheating and Reducing Friction

Role of Lubrication:

Proper lubrication reduces friction between the rolls and the material, which prevents excessive wear. The choice of lubricant depends on the roll material and the operating temperature. A high-quality lubricant will form a protective layer on the roll surface, preventing direct contact with the metal and minimising wear.

Lubrication should be checked regularly, as inadequate lubrication can lead to higher friction, heat buildup, and premature roll failure.

Cooling Systems:

Roll cooling is critical for preventing thermal fatigue. By using effective water or oil cooling systems, the rolls are kept at an optimal temperature. Proper cooling ensures that the rolls don’t experience thermal distortion, which can affect the overall quality of the steel products.

Water cooling systems are most commonly used due to their efficiency in maintaining a steady temperature, while oil cooling systems are beneficial for maintaining lubrication in high-temperature areas.

Proper Roll Alignment and Setup: Minimising Stress and Wear

Importance of Roll Alignment:

Misalignment of the rolls can lead to uneven pressure distribution, causing localised wear and increasing the stress on certain areas of the roll. Regular roll alignment checks are vital to ensure the rolls are properly positioned and functioning optimally.

Roll Setup Best Practices:

Ensuring proper roll setup means that force is distributed evenly across the roll’s surface. This helps in reducing localised wear and minimising the potential for uneven damage. Ensuring the right setup during each operation and making necessary adjustments can significantly increase the roll’s lifespan.

Predictive Maintenance: Leveraging Technology for Early Detection

Condition Monitoring Systems:

Condition monitoring systems use sensors to track the health of the rolls in real-time. These systems can monitor factors such as vibration, temperature, and load, providing data that can help operators identify potential issues before they fail. These sensors play a key role in predictive maintenance.

Predictive Analytics:

With advancements in AI and machine learning, predictive analytics can be employed to forecast when the rolling mill machinery is likely to fail. By analysing patterns of wear and operational data, predictive models can estimate the remaining life of the rolls, allowing operators to schedule maintenance or replacement proactively.

Benefits of Predictive Maintenance:

By implementing predictive maintenance, steel mills can experience reduced downtime, better planning for maintenance activities, and lower maintenance costs. With the right data, mills can extend the life of their rolls and improve the overall efficiency of their operations.

Common Mistakes to Avoid in Rolling Mill Machinery Maintenance

1. Neglecting Regular Inspections:

Failing to perform routine inspections can lead to small issues growing into major problems. Identifying and addressing early signs of damage can prevent costly repairs and unplanned downtime.

2. Using Incorrect Lubricants or Coolants:

Using the wrong lubricant or coolant for the specific conditions of the mill can increase wear and cause irreversible damage to the rolls. Always ensure that the chosen lubricants and coolants are compatible with the operating conditions.

3. Ignoring Surface Damage:

Surface damage, even if it seems minor, should never be ignored. Timely repairs can prevent further deterioration and prolong the roll’s life.

4. Inadequate Roll Alignment Checks:

Failure to regularly check and adjust roll alignment can result in uneven wear, leading to increased maintenance costs and more frequent roll replacements.

When to Replace Rolls: Understand the Signs of Irreparable Damage

There are instances when rolls reach a point where repair is no longer a viable option. Signs that it’s time to replace the rolls include:

- Excessive cracking that affects structural integrity, making the roll unsafe for continued use.

- Severe wear that compromises the roll’s ability to apply consistent pressure, resulting in poor product quality and operational inefficiencies.

- Deformation that cannot be corrected by resurfacing, often caused by prolonged stress or thermal fatigue, which leads to permanent changes in shape.

If repairs no longer restore the roll’s original functionality or if the costs of repairs exceed the cost of replacement, it’s more economical to replace the rolls. Waiting too long can lead to significant downtime, further damage to rolling mill machinery, and the production of subpar products, which can all negatively affect your business’s bottom line.

Cost-Benefit Analysis:

Deciding whether to repair or replace rolls requires a thorough cost-benefit analysis. If the cost of repairs is close to or exceeds the cost of replacing the rolls, then replacement may be the more economical option. Keeping track of the rolls’ performance and maintenance history will help in making an informed decision.

Improving ROI with Long-Term Roll Management:

A proactive approach to roll maintenance can help reduce long-term equipment costs. By extending the lifespan of your rolls and reducing downtime, you can improve the overall return on investment (ROI) of your rolling mill. Regular maintenance ensures fewer unexpected failures, lowering the need for expensive repairs and replacements. Additionally, optimised roll performance leads to more consistent product quality, which can result in higher customer satisfaction and retention, further boosting your profitability.

Ensure Peak Performance with The Steefo Group’s Roll Maintenance Solutions

At The Steefo Group, we understand that maintaining the health of your rolling mill rolls is crucial for maximising productivity and minimising costly downtime. Our advanced roll maintenance solutions are designed to optimise the lifespan of your rolls, ensuring they perform at their best throughout their service life. With years of experience in the steel industry, we offer expert guidance on inspection, lubrication, alignment, and cooling systems, all tailored to your unique needs.

By choosing Steefo, you’re not just getting premium products; you’re partnering with a team committed to enhancing your operational efficiency. Our predictive maintenance and condition monitoring services give you the insight you need to prevent issues before they arise, keeping your mill running smoothly.

Contact The Steefo Group at +91 87589 98607 or send us an email to marketing@thesteefogroup.com to discover how our roll maintenance solutions can boost your mill’s performance and reduce operating costs.

Also Read:

The Importance of Regular Maintenance and Upkeep for Rolling Mill Machinery