Shearing machines are indispensable in the metalworking industry, including steel rolling mills. These machines are designed to cut metal bars, plates, or sheets with precision, efficiency, and consistency. For businesses operating in this sector, the right shearing machine can significantly enhance productivity and product quality. This guide aims to provide insights into selecting the most suitable option for your rolling mill, ensuring you make a well-informed decision that meets your needs.

Key Factors to Consider When Choosing a Shearing Machine

Choosing the right shearing machine involves evaluating several critical factors. Each factor plays a vital role in ensuring the machine you select aligns perfectly with your operational requirements and business goals. Here’s a detailed look at these key factors:

1. Cutting Capacity

The cutting capacity of a shearing machine refers to the maximum thickness and width of the material it can cut. This is one of the most crucial aspects to consider because it directly affects the types of projects you can undertake. When evaluating cutting capacity, keep in mind the typical dimensions of the materials you work with. For instance, if your rolling mill primarily deals with thick steel bars, you will need a machine that can handle substantial thickness without compromising precision. On the other hand, if you work with thinner bars, a machine with a lower cutting capacity is more cost-effective.

2. Material Compatibility

Different shearing machines are designed to handle various materials, such as steel, aluminum, copper, and more. It’s essential to choose a machine compatible with the materials processed in your rolling mill. Material compatibility ensures not only longevity of the machine but also quality of the cuts. For steel rolling mills, machines specifically designed for cutting steel would be the best choice. These machines are built to withstand the hardness and toughness of steel, providing clean and accurate cuts consistently.

3. Precision Requirements

Precision is paramount in metal-cutting operations. The quality of your final product hinges on how accurately the material is cut. High-precision shearing machines are equipped with advanced features that allow for fine adjustments, ensuring each cut meets the exact specifications. When considering precision requirements, assess the tolerance levels acceptable for your projects. If your rolling mill produces components that require tight tolerances, investing in a high-precision machine is crucial. Conversely, for projects with more lenient tolerances, a standard precision machine might be adequate.

4. Safety Features

Safety should never be compromised in any industrial setting, and shearing machines are no exception. Modern versions come equipped with various safety features designed to protect operators and prevent accidents. Consider the machine’s compliance with industry safety standards and regulations. Ensuring the safety of your workforce protects your employees and also minimizes downtime and potential liabilities.

5. Ease of Operation

The ease of operation is another critical factor to consider. A user-friendly shearing machine can significantly reduce training time and increase overall efficiency. Look for machines with intuitive controls, clear displays, and automated features that simplify the cutting process. Some advanced models offer programmable settings, allowing operators to save and recall specific cutting parameters for repeated tasks. This feature can be particularly beneficial for rolling mills that handle a variety of projects, as it streamlines the workflow and reduces the likelihood of errors.

6. Space and Installation Requirements

The physical space available in your facility and the installation requirements of the shearing machine are practical considerations that can’t be overlooked. Measure the available space in your rolling mill and compare it with the dimensions of the machines you are considering. Ensure there is adequate room for installation, operation, and maintenance activities. Additionally, consider the power supply and other infrastructure requirements of the machine. Some machines may require specific electrical setups or foundations, so it’s essential to account for these needs in your planning.

Cost Considerations

When selecting a shearing machine for your steel rolling mill, the cost is a crucial factor that impacts your investment and operational budget. It’s essential to evaluate not only the initial purchase price but also the long-term financial implications. Here are some key cost considerations:

1. Initial Purchase Price

The upfront cost of a shearing machine varies significantly based on its features, capacity, and brand. High-end models with advanced capabilities and higher cutting capacities tend to be more expensive. While it might be tempting to opt for a cheaper machine, it’s vital to ensure that it meets your specific requirements and offers reliable performance.

2. Operational Costs

Beyond the purchase price, consider the operational costs associated with running the machine. These include energy consumption, labour costs, and the cost of consumables such as blades. Energy-efficient machines might have a higher initial cost but can lead to significant savings in the long run. Additionally, machines that require less manual intervention can reduce labor costs and increase overall productivity.

3. Maintenance Costs

Regular maintenance is necessary to keep the shearing machine in optimal working condition. Evaluate the cost of spare parts, the availability of technical support, and the frequency of required maintenance. Machines from reputable manufacturers often come with warranties and reliable customer support, which can mitigate some maintenance costs.

4. Total Cost of Ownership (TCO)

The total cost of ownership encompasses all costs associated with the shearing machine over its lifecycle, including purchase, operation, maintenance, and disposal. By calculating the TCO, you can gain a comprehensive understanding of the machine’s financial impact on your business. This approach ensures you make a well-informed decision that balances initial costs with long-term benefits.

Maintenance and Durability

The durability and maintenance requirements of a shearing machine are critical factors that affect its performance and longevity. A well-maintained machine ensures consistent operation and also extends its service life, providing a better return on investment. Here’s what you need to know about maintenance and durability:

1. Durability

A durable machine is built to withstand the rigors of daily operation in a rolling mill. Look for options constructed from high-quality materials such as hardened steel, which can resist wear and tear. The design and engineering of the machine also play a role in its durability. Machines with robust frames and components are less likely to suffer from operational failures and downtime.

2. Regular Maintenance

Regular maintenance is essential to keep the shearing machine in peak condition. This includes routine inspections, lubrication of moving parts, and timely replacement of worn-out components. Establishing a maintenance schedule can help prevent unexpected breakdowns and ensure smooth operation. Many modern machines come with maintenance alerts and diagnostics features, making it easier to keep track of their condition.

3. Availability of Spare Parts

The availability of spare parts is a crucial aspect of maintenance. When choosing a shearing machine, consider the ease of obtaining replacement parts. Machines from well-known manufacturers usually have a readily available supply of spare parts. This reduces downtime in case of component failure and ensures that the machine can be quickly repaired and returned to service.

4. Technical Support and Training

Access to technical support and training is vital for the effective maintenance and operation of the machine. Manufacturers that offer comprehensive training programs help your team understand the machine’s functionalities and maintenance requirements. Additionally, reliable technical support can assist in troubleshooting issues and providing solutions, minimizing disruption to your operations.

5. Preventive Maintenance Programs

Implementing a preventive maintenance program can enhance the durability and reliability of your shearing machine. Such programs involve regular checks and proactive maintenance activities aimed at identifying and addressing potential issues before they escalate. Preventive maintenance can significantly extend the lifespan of the machine and improve its overall efficiency.

Frequently Asked Questions

1. What are the key considerations for ensuring precise cuts in different materials?

Ensuring precise cuts in various materials involves several key considerations:

- Material Type and Thickness: Different materials have different hardness levels, which affects the cutting process. Ensure the shearing machine is compatible with the material you are working with and can handle its thickness without causing deformation or inaccuracies.

- Blade Quality and Sharpness: High-quality, sharp blades are crucial for achieving clean and precise cuts. Regularly inspect and maintain the blades to ensure they remain in optimal condition.

- Machine Settings: Adjusting the machine settings to match the specific requirements of the material is essential. This includes settings for blade gap, cutting angle, and pressure.

- Operator Skill: Skilled operators can significantly influence the precision of cuts. Providing adequate training and ensuring operators understand the machine’s functionalities can improve accuracy.

2. How can safety features in shearing machines enhance workplace safety?

Safety features in shearing machines are designed to protect operators and prevent accidents. Key features include:

- Emergency Stop Buttons: Allow operators to quickly stop the machine in case of an emergency, preventing potential injuries.

- Safety Guards: Physical barriers that protect operators from cutting blades and moving parts, reducing the risk of accidental contact.

- Two-Hand Operation Controls: Require the operator to use both hands to activate the machine, ensuring they are not in a danger zone when the machine is operating.

These features help create a safer working environment, reduce the risk of injuries, and ensure compliance with safety regulations.

3. What maintenance practices are crucial to prolonging the lifespan of a shearing machine?

To prolong the lifespan of a shearing machine, regular maintenance practices are essential:

- Routine Inspections: Conduct regular inspections to identify wear and tear on components. Early detection of issues can prevent major breakdowns.

- Lubrication: Ensure all moving parts are adequately lubricated to reduce friction and prevent premature wear.

- Blade Maintenance: Regularly sharpen and replace blades to maintain cutting efficiency and precision.

- Cleaning: Keep the machine clean to prevent dust and debris from affecting its performance.

- Calibration: Periodically calibrate the machine to ensure all settings are accurate and the machine operates as intended.

How can I optimise the total cost of ownership when investing in a shearing machine?

Optimising the total cost of ownership (TCO) involves several strategies:

- Invest in Quality: Choose a high-quality machine that, although possibly more expensive upfront, will offer better performance and longevity.

- Energy Efficiency: Select energy-efficient machines to reduce ongoing operational costs.

- Preventive Maintenance: Implement a preventive maintenance program to minimise downtime and extend the machine’s lifespan.

- Training: Invest in operator training to ensure the machine is used correctly and efficiently, reducing the likelihood of misuse and damage.

- Spare Parts Availability: Ensure easy access to spare parts to minimise downtime during repairs.

By considering these factors, you can optimise your investment and ensure the shearing machine remains a valuable asset to your rolling mill operations.

Looking to Invest in Premium Quality Shearing Machines?

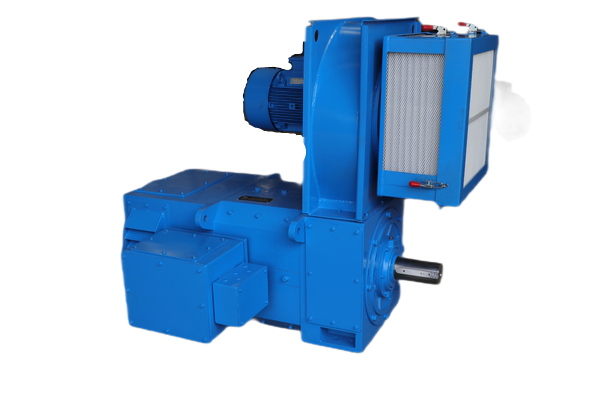

Improve your steel rolling mill operations with top-tier shearing machines manufactured by The Steefo Group. With over 45+ years of expertise and experience, we manufacture high-quality rolling mill machinery including shearing equipment in our state-of-the-art facilities.

Invest in precision, efficiency, and reliability with our cutting-edge shearing solutions. Our machines are engineered to meet the highest standards, ensuring exceptional performance and durability. Whether you need to handle thick steel plates or delicate sheets, our shearing machines deliver unparalleled accuracy and speed.

Contact us at +91 98240 76873 or drop a mail at marketing@thesteefogroup.com to learn more about our range of premium shearing machines and how they can transform your rolling mill operations. Reach out now and secure the future of your production line with the best in the industry!