Rolling mills play an indispensable role in industries such as construction, automotive, and infrastructure, producing essential materials like bars, rods, sheets, and coils. Investing in a turnkey rolling mill project is a major decision, and it is crucial to understand the various costs involved to make an informed and strategic choice.

This blog post will explore the cost breakdown of turnkey rolling mill projects, providing in-depth insights into every phase of the project. It will also highlight how turnkey solutions can streamline your project execution, ensuring that you get value for every dollar spent.

What Are Turnkey Solutions for Rolling Mills?

Before diving deep into the cost breakdown, it’s important to understand the concept of a turnkey solution for rolling mills. A turnkey solution refers to a comprehensive service package where the rolling mill manufacturer provides everything from design, procurement, installation, and commissioning to after-sales service. The term “turnkey” signifies that the project is delivered ready for immediate operation without the client needing to manage multiple contractors or suppliers.

For a rolling mill, turnkey solutions offer a hassle-free approach by providing:

- Design and engineering services to customise the mill to meet specific needs.

- Procurement of equipment and materials.

- Installation and commissioning, ensuring everything works as expected.

- Project management to keep everything on track.

- After-sales services include maintenance, training, and support.

Now that we understand what turnkey solutions entail, let’s break down the key components of cost in a turnkey rolling mill project.

Design and Engineering Costs

The design and engineering phase is one of the most critical stages of any turnkey rolling mill project. This is where the blueprint of the entire facility is developed. It covers everything from plant layout to equipment specifications, ensuring that the mill will operate efficiently, safely, and within budget.

Factors Affecting Design and Engineering Costs:

- Complexity and Scale of the Project: The more intricate and large the rolling mill, the higher the design and engineering costs. Projects that require advanced technologies, such as automated control systems or specialised rolling techniques, will require more detailed engineering, thus increasing costs.

- Customisation Requirements: If the mill needs to be customised to produce specific products, the design phase will take longer and incur higher costs. Custom designs usually require additional engineering hours to ensure the mill meets production targets while maintaining optimal operational efficiency.

- Environmental and Safety Considerations: Rolling mills must adhere to strict safety and environmental standards. Designing the mill in compliance with these regulations may require more detailed planning and specialised design adjustments, which could further increase costs.

Estimated Cost:

Typically, design and engineering costs account for 5% to 10% of the total project cost. However, if the rolling mill requires significant customisation or additional complexity, these costs may exceed the normal range.

Equipment and Machinery Costs

The equipment and machinery required to operate the rolling mill are the core of the project. This is the most expensive part of the investment, as rolling mills require highly specialised equipment to produce high-quality rolled products.

Key Equipment in a Rolling Mill:

- Reheating Furnace: Used to heat the raw materials (such as billets) before they are fed into the rolling stands. This equipment is crucial in achieving the desired material properties.

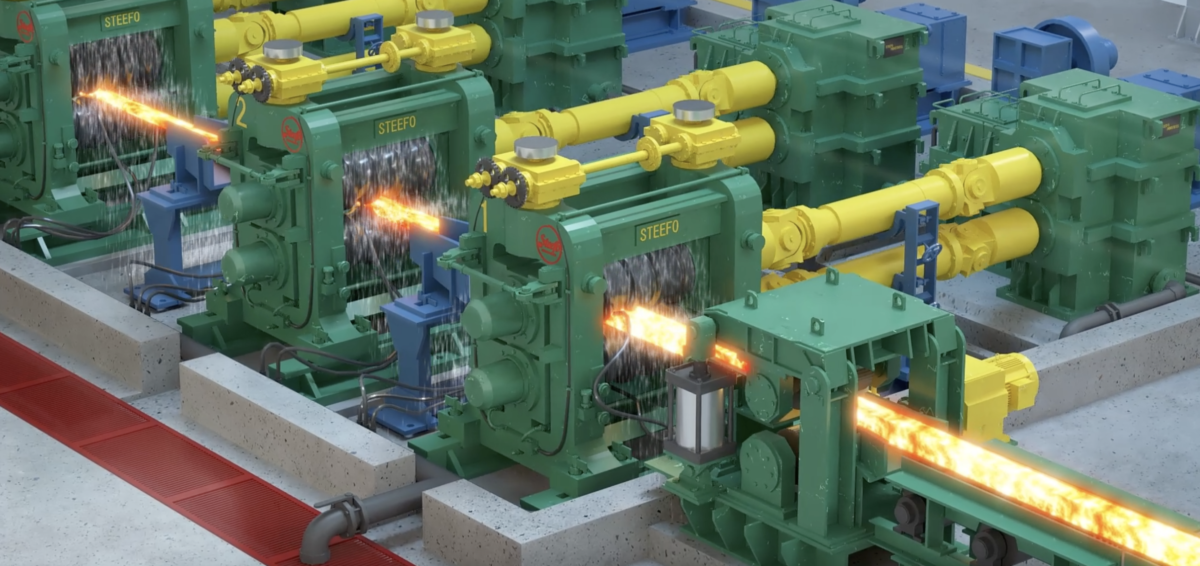

- Rolling Stands: These are the heart of the rolling mill, where the material is shaped and reduced to the desired thickness. Rolling stands come in different configurations depending on the product being manufactured, such as bar mills, wire rod mills, or section mills.

- Coiling and Cooling Systems: After the rolling process, materials need to be cooled and coiled to make them more manageable for transportation and storage. These systems ensure that the finished products are handled efficiently.

- Auxiliary Equipment: This includes the electrical systems, motors, drives, material handling systems, and automation equipment that enable smooth operation.

Factors Influencing Equipment Costs:

- Type of Rolling Mill: Hot rolling mills typically require more sophisticated equipment due to the high temperatures and more extensive processes involved. Cold rolling mills are generally less expensive but still involve specialised machinery.

- Automation and Technology: Fully automated mills with sophisticated control systems tend to cost more. The integration of advanced technologies such as artificial intelligence and machine learning for predictive maintenance and process optimisation can significantly raise the equipment costs.

- Supplier and Brand: The cost of equipment also depends on the brand and quality. Reputed rolling mill manufacturers, like The Steefo Group, offer high-quality, durable equipment that tends to come with a higher price tag, but this investment ensures long-term reliability.

Estimated Cost:

Equipment costs usually make up 40% to 60% of the total cost of a turnkey rolling mill project. The specific percentage depends on the type of equipment, automation level, and scale of the mill.

Installation and Commissioning Costs

Once the equipment is procured, the next step is to install it and ensure it operates efficiently. Installation includes everything from setting up the machinery to connecting electrical systems and integrating automation controls. Commissioning, on the other hand, is the process of testing the equipment to ensure that everything functions as per the design specifications.

Factors Affecting Installation and Commissioning Costs:

- Site Preparation: If the factory site requires significant modifications (such as reinforcement of structures or new electrical infrastructure), installation costs will rise.

- Labour and Expertise: Skilled labour is required for the installation of rolling mill equipment, particularly when it comes to sophisticated machinery. Experienced technicians and engineers are essential for ensuring that the installation is done correctly.

- Testing and Calibration: Once installed, the machinery needs to be tested and calibrated to meet the production standards. This step ensures that the mill produces high-quality products while maintaining efficiency.

Estimated Cost:

Installation and commissioning typically account for 10% to 15% of the total project cost. The exact cost will depend on the complexity and size of the rolling mill.

Procurement Costs

Procurement costs involve the acquisition of all materials, tools, and systems necessary for the mill’s construction. This includes purchasing raw materials like steel, alloys, and electrical components, as well as specialised tools and systems needed for the smooth operation of the rolling mill.

Key Procurement Considerations:

- Material Quality: The quality of raw materials directly affects the durability and efficiency of the rolling mill. High-quality materials may cost more initially but lead to fewer repairs and downtime in the long run.

- Supplier Network: Working with reliable and cost-effective suppliers can significantly reduce procurement costs. However, purchasing from multiple suppliers can add complexity and lead to higher logistics costs.

- Lead Time and Shipping: If materials are sourced globally, shipping costs, customs duties, and lead times can further increase procurement expenses.

Estimated Cost:

Procurement typically accounts for 10% to 20% of the overall project cost, depending on the specific materials required and where they are sourced from.

Project Management and Overhead Costs

Project management is essential for ensuring that a turnkey rolling mill project progresses on schedule and within budget. Project managers coordinate between design, procurement, installation, and commissioning teams to ensure smooth execution.

Key Aspects of Project Management:

- Scheduling and Coordination: Project managers handle timelines, resources, and task coordination to ensure that all phases of the project align.

- Quality Control: Ensuring the project meets all quality standards is crucial. Project managers work closely with the installation and engineering teams to guarantee that the equipment and systems are installed according to design specifications.

- Risk Management: Project managers must be prepared to handle any unforeseen challenges, such as delays, cost overruns, or technical issues.

Estimated Cost:

Project management and overheads generally represent 5% to 10% of the total project cost, depending on the project scale and complexity.

Electrical and Automation Systems Costs

Electrical and automation systems are integral to the operation of modern rolling mills. These systems include power distribution, control panels, PLC systems, SCADA systems, sensors, and drives that enable the mill to operate efficiently.

Key Electrical and Automation Components:

- Control Systems: PLC and SCADA systems enable real-time monitoring and control of the mill’s operations. These systems ensure that the mill runs smoothly and that any issues are detected early.

- Automation Equipment: Automated handling systems, such as robot arms, material transfer systems, and roll change equipment, can drastically improve production efficiency.

- Safety and Monitoring Systems: Ensuring the safety of the mill workers and preventing any potential damage to the equipment is essential. This involves installing safety systems, alarms, and sensors.

Estimated Cost:

Electrical and automation systems typically account for 5% to 15% of the total turnkey rolling mill project cost. The specific percentage depends on the level of automation and the complexity of the electrical systems.

Maintenance and After-Sales Services

Once the rolling mill is operational, ongoing maintenance is essential to ensure it continues to function efficiently. Regular maintenance minimises downtime, prevents costly repairs, and ensures that the mill operates at its full capacity.

Key Considerations for Maintenance Costs:

- Spare Parts: Rolling mills require various spare parts, including rolls, motors, bearings, and sensors. Ensuring a steady supply of spare parts is essential for minimising downtime.

- Service Contracts: Many manufacturers offer service contracts for regular maintenance, which may include preventive maintenance, inspections, and equipment overhauls.

- Long-Term Support: After-sales services, including training, technical support, and troubleshooting, help ensure the long-term success of the mill.

Estimated Cost:

Maintenance and after-sales services can cost 5% to 10% annually, based on the terms of the service contract and the level of support required.

Miscellaneous Costs

There are several other costs associated with a turnkey rolling mill project that may not be immediately apparent but are essential to consider.

Key Miscellaneous Costs:

- Land and Site Acquisition: If the factory site needs to be purchased, this can significantly increase project costs.

- Permits and Licensing: Obtaining the necessary permits and licenses for operating the mill can involve additional costs, particularly if there are local regulations to adhere to.

- Insurance and Contingency: Insurance coverage and contingency funds are necessary to cover unforeseen risks or issues that may arise during the construction and operation phases.

Estimated Cost:

Miscellaneous costs usually account for 5% to 10% of the total project cost.

Conclusion

Setting up a turnkey rolling mill is a substantial investment, but with the proper planning and understanding of the cost breakdown, it can be an immensely profitable venture. From design and engineering to equipment procurement, installation, and after-sales services, each component plays a crucial role in the success of the project.

Working with experienced rolling mill manufacturers like The Steefo Group ensures that the project is managed effectively and that the final product meets your specifications. By carefully considering and managing each cost element, businesses can achieve a turnkey solution that delivers long-term value and ensures efficient mill operation.

Remember that while turnkey solutions come with a higher upfront cost, they save time, reduce project complexity, and minimise risks. This approach allows businesses to focus on production, knowing that their rolling mill is in capable hands.

Frequently Asked Questions

1. What are the benefits of choosing a turnkey rolling mill project over building a mill from scratch?

Choosing a turnkey rolling mill project offers several advantages, including reduced complexity, time savings, and minimised risk. With a turnkey solution, you get a fully integrated system where the manufacturer handles every aspect of the project, from design and procurement to installation and maintenance. This ensures faster commissioning, reduced project delays, and cost-effective operations. Additionally, turnkey providers offer expert consultation, reducing the need for in-house technical expertise.

2. How can I determine if my business needs a hot rolling mill or a cold rolling mill for a turnkey project?

The choice between a hot rolling mill and a cold rolling mill depends on the final product and its intended application. Hot rolling mills are typically used for producing thick products like plates, beams, or bars at high temperatures, while cold rolling mills are used for thinner, high-precision products such as sheet metal, coils, and strips. Understanding the type of material you want to produce, its required thickness, and its application will help you make the right decision for your turnkey rolling mill project.

3. What is the typical timeline for a turnkey rolling mill project to be completed?

The timeline for completing a turnkey rolling mill project varies depending on several factors, such as the project scale, customisation requirements, and the complexity of equipment. On average, a turnkey rolling mill project can take anywhere from 12 to 24 months to complete. This includes the phases of design, procurement, installation, commissioning, and testing. Larger or more specialised mills may require more time to install and fine-tune the equipment to meet production goals.

4. Can I expect warranty coverage for the equipment used in a turnkey rolling mill project?

Yes, most reputable rolling mill manufacturers offer warranty coverage for the equipment supplied in a turnkey rolling mill project. The warranty typically covers any defects in material or workmanship and ensures that the equipment functions as promised. Warranty periods may vary depending on the manufacturer and the type of equipment, but generally range from 1 to 3 years. Additionally, many suppliers offer extended service contracts and after-sales support to ensure long-term maintenance and performance.

5. How does automation in a turnkey rolling mill improve production efficiency?

Automation in a turnkey rolling mill significantly enhances production efficiency by reducing human intervention, minimising errors, and optimising machine performance. Automated systems, such as PLC controls and SCADA systems, allow for real-time monitoring and data-driven adjustments, leading to consistent product quality. Robotic material handling, automatic roll changes, and precision control over the rolling process also reduce downtime and improve throughput. By integrating advanced automation, businesses can lower operational costs while maximising output.

Ready to Invest in a Turnkey Rolling Mill Solution?

If you’re looking to optimise your manufacturing process and ensure long-term success, a turnkey rolling mill solution is the key to achieving efficiency, cost-effectiveness, and seamless production. Whether you’re expanding your operations or starting a new project, partnering with an experienced rolling mill manufacturer guarantees high-quality machinery, expert project management, and support from start to finish.

Don’t let the complexity of setting up a rolling mill overwhelm you. The Steefo Group offers comprehensive turnkey solutions that handle every aspect of your project, from design and procurement to installation and maintenance. With decades of experience and a commitment to excellence, we deliver results that align with your business goals.

Contact us today at +91 87589 98607 or write to us at marketing@thesteefogroup.com to learn how we can bring your rolling mill project to life and set you up for success. Let’s build your future together, with a customised solution tailored to your needs!