Rolling mills are the backbone of modern manufacturing. Without them, the metal products that form the foundation of industries like steel, automotive, construction, and even aerospace, would not exist in the forms or quality we depend on. Whether it’s a steel beam supporting a high-rise building or a thin sheet of metal used in automotive parts, rolling mills shape and strengthen metal products in ways that are essential to the functionality and durability of these industries.

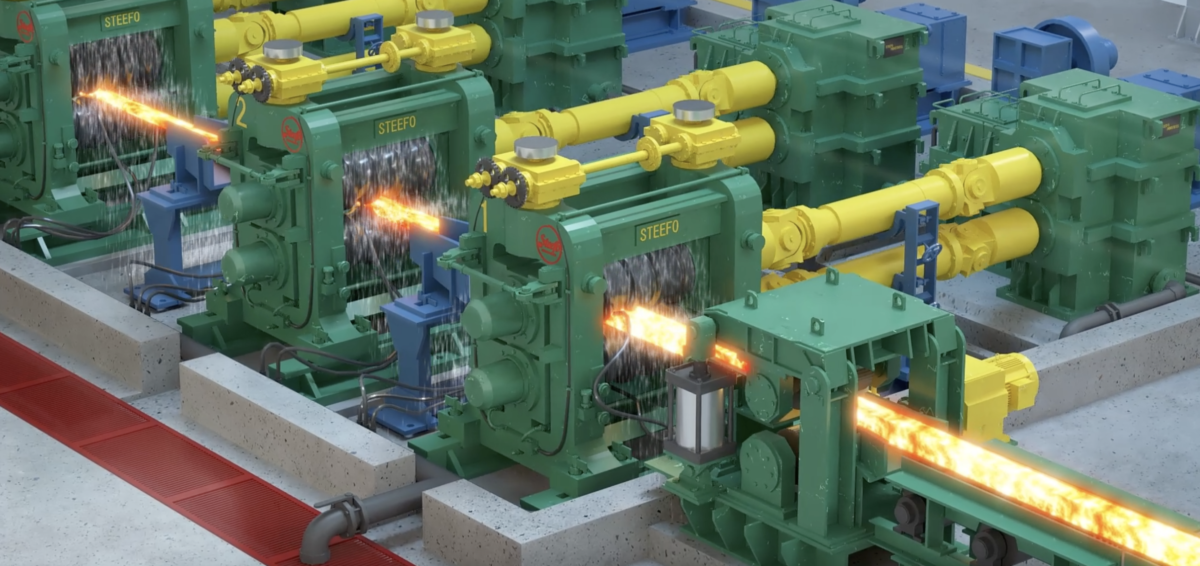

In today’s world, metal manufacturing is one of the most critical sectors, supporting infrastructure, transportation, and machinery, and rolling mills are the machines that make it all happen. In this post, we will take a deep dive into the workings of rolling mills, how they shape and strengthen metals, the impact they have on industries, and the latest advancements in technology used in modern mills. We’ll also explore why rolling mills are essential for producing high-quality steel and how The Steefo Group’s rolling mill solutions lead the way in offering customised, efficient, and high-quality production processes.

What Are Rolling Mills?

At the most basic level, rolling mills are machines used in the metal manufacturing process to shape and strengthen metal by passing it through a series of rollers. These machines apply heat, pressure, and mechanical force to metal, causing it to deform into specific shapes, such as sheets, bars, beams, and rods.

Function of Rolling Mills

The fundamental function of a rolling mill is to reduce the thickness of metal and elongate it while maintaining or adjusting its width. This transformation of metal into various shapes is known as rolling. In steel rolling mills, the process usually involves heating the metal to high temperatures to make it more malleable, although cold rolling can also be performed at room temperature for specific applications where tight tolerances and enhanced surface finishes are required.

Rolling mills are primarily used for producing metal products such as:

- Steel sheets for automotive parts, structural applications, and appliances

- Steel beams and reinforcement bars (like TMT bars) are used in construction.

- Plates and coils for industrial machinery

How Rolling Mills Shape Metal

Rolling mills shape metal by applying mechanical pressure and, in some cases, heat, to compress and elongate it. This shaping process is what enables metal to be formed into products that can be used for diverse applications.

The Rolling Process

The process begins by heating the metal to the desired temperature, making it more ductile and easier to work with. Once the metal has reached the right temperature, it is passed through rollers that gradually compress it. The metal undergoes several stages of rolling, with each stage refining its thickness, shape, and finish.

The rolling process consists of multiple stages, including:

- Initial Heating: Metal is heated to a temperature where it becomes malleable but not molten. In steel rolling mills, this is often done in a furnace.

- Compression and Elongation: The metal is passed through a series of rollers, each set reducing the thickness further and stretching the metal.

- Cooling: In TMT bar rolling mills, rapid cooling is done after the shaping process to increase the strength of the material.

- Finishing: The final shape is achieved with high precision, depending on the type of rolling mill used.

Key Mechanisms Involved

The key forces at work in rolling mills include compression and deformation. These forces allow the metal to flow into the desired shape. As the metal passes through the rollers, the compression causes the metal to elongate while reducing its thickness. This is a crucial step in shaping metal products with uniform dimensions, ensuring they meet strict industry standards.

The deformation that takes place is critical in achieving the right grain structure within the metal. The controlled deformation process helps to make the material denser and more uniform, which directly contributes to its mechanical properties.

Surface Finish and Defect Removal

Rolling mills also play an important role in improving the surface quality of metal. Surface defects such as cracks, oxidation, and scale (a flaky layer of oxide that forms on the surface) are common during metalworking processes. The pressure applied during rolling helps smooth out these imperfections, resulting in a clean and uniform surface finish. This is especially important for industries like automotive and construction, where both the aesthetic and functional qualities of metal products are critical.

Strengthening Metal Through Rolling Mills

The process of shaping metal in rolling mills does more than change its dimensions. It also significantly strengthens the material, improving its mechanical properties and making it more suitable for demanding applications.

Mechanical Properties Enhanced by Rolling

When metal is passed through the rolling mill, it undergoes strain, which alters its mechanical properties. Rolling increases the strength, toughness, ductility, and fatigue resistance of the metal, which makes it better suited for the harsh conditions it may face in real-world applications.

- Strength: The metal becomes stronger due to the grain refinement and strain hardening that occur during the rolling process. This makes it able to withstand greater forces without breaking or deforming.

- Toughness: The toughness of the material is enhanced, improving its ability to absorb energy without fracturing. This is essential for parts used in high-stress environments, such as construction beams or automotive components.

- Ductility: The rolling process enhances ductility, allowing the metal to be stretched and formed without cracking. This is particularly important for industries that require metal to be bent, twisted, or formed into intricate shapes.

- Fatigue Resistance: Metals processed through rolling are more resistant to fatigue, meaning they can withstand repeated stress cycles without failing. This is critical in components that experience dynamic loading, such as suspension components in vehicles or structural beams in buildings.

Grain Structure and Durability

A major benefit of the rolling process is the improvement of the grain structure of the metal. As the metal is compressed and elongated, the grains (crystals) within the metal become more uniform in size and shape. This refinement in grain structure significantly increases the metal’s strength and durability. Rolling mills effectively make the metal more homogeneous, which helps it to resist wear and tear.

A uniform grain structure also improves the ductility and toughness of the metal, making it better able to withstand high loads, temperature variations, and impact stresses.

Impact on Real-World Applications

The benefits of these enhanced properties are immediately visible in industries like construction, automotive, and aerospace. Rolled steel beams in construction, for example, need to have high strength and durability to support heavy loads over long periods. The rolling process makes these beams capable of handling such loads without bending or breaking.

In the automotive industry, rolling mills produce parts that are designed to endure dynamic forces and harsh conditions, such as chassis and body components. Rolling mills ensure these parts are not only the right shape but also have the right mechanical properties to enhance performance and longevity.

Why Rolling Mills Are Essential for Quality Steel Production

Steel production requires a combination of precision, strength, and quality to meet the ever-demanding standards of the market. This is where steel rolling mills come into play, as they are instrumental in shaping and strengthening steel to meet these requirements.

Importance of Steel in Manufacturing

Steel is the most widely used metal in the world, and it is crucial in almost every industry. Whether it’s construction, transportation, or manufacturing, steel is at the core of the world’s infrastructure. Steel produced through rolling mills is essential for ensuring that the final products meet rigorous standards of strength, durability, and quality.

Key Benefits of Steel Rolling Mills

Steel rolling mills provide several benefits that directly influence the final product’s quality:

- Consistent Thickness and Dimensions: Precision is key in steel production. Steel rolling mills ensure that the steel products have consistent thickness, which is vital for their strength and performance in applications like construction.

- Improved Surface Quality: Rolling mills help improve the surface finish of the steel, ensuring that the steel products are free from defects like cracks, oxidation, or other surface blemishes.

- Elimination of Defects: Steel products that go through the rolling mill process have fewer internal defects, such as porosity or slag, making them more reliable and stronger.

The Direct Impact on Strength and Durability

The advantages of rolling mills, such as uniform thickness, enhanced surface quality, and defect elimination, lead to stronger, more durable steel products that meet the stringent demands of various industries. Steel used in construction, for example, must resist extreme loads and environmental factors. Steel rolling mills ensure that the material is up to the task.

The Role of Technology in Modern Rolling Mills

The steel and metal manufacturing industries are rapidly evolving, and technology has played a crucial role in transforming how rolling mills operate today. Modern mills are equipped with cutting-edge technologies that improve both efficiency and the final product’s quality.

Automation and Innovation

Automation has revolutionised the rolling mill industry. Automated systems are used to control variables such as speed, pressure, and temperature, ensuring consistency and precision in every batch. These systems allow for real-time adjustments to the rolling process, reducing defects and improving overall production efficiency.

Sustainability and Energy Efficiency

With increasing environmental concerns, many rolling mills are focusing on sustainability. Advancements such as waste heat recovery, regenerative heating systems, and energy-efficient motors have helped reduce the environmental footprint of mills. These technologies not only reduce energy consumption but also lower emissions, making the steel rolling process more sustainable.

The Steefo Group’s Role in Rolling Mill Innovation

The Steefo Group stands at the forefront of rolling mill technology. Our steel rolling mills incorporate the latest advancements in automation, energy efficiency, and sustainability to provide clients with high-quality, cost-effective, and environmentally friendly solutions. At Steefo, we are committed to providing cutting-edge solutions that meet the demands of modern manufacturing.

Bottomline

Rolling mills are essential for shaping and strengthening metal products that are vital to industries worldwide. Whether producing steel for construction, automotive parts, or infrastructure, rolling mills play a critical role in ensuring metal products have the right properties for their intended use.

Through advancements in technology, automation, and sustainability, modern rolling mills continue to improve production efficiency, reduce environmental impact, and enhance product quality. Steefo Group is proud to lead the industry with innovative rolling mill solutions that meet the growing demands of the global market.

Frequently Asked Questions

1. What is a rolling mill?

A rolling mill is a machine that shapes metal by passing it through a series of rollers. The metal is either heated or processed at room temperature to reduce its thickness and change its shape.

2. How do rolling mills work?

Rolling mills work by applying heat and mechanical pressure to metal, causing it to elongate and compress, shaping it into the desired form.

3. What are the advantages of using rolling mills in steel production?

Rolling mills offer benefits like consistent thickness, improved surface quality, and the elimination of internal defects, which result in stronger, more durable steel products.

4. How are rolling mills used in the construction industry?

In construction, rolling mills produce steel products such as beams, rods, and reinforcement bars, ensuring that these materials meet the strength and durability requirements for building structures.

5. Why is Steefo’s Steel Rolling Mill Technology Ideal for Strengthening Metal Products?

Steefo’s rolling mills integrate advanced automation, energy-efficient systems, and sustainable practices to deliver high-quality, precise, and environmentally friendly metal products.

Get in Touch with The Steefo Group for Customised Rolling Mill Solutions

At The Steefo Group, we understand that every manufacturing process is unique. That’s why we offer customised rolling mill solutions tailored to your specific needs. Whether you’re in the steel, automotive, construction, or any other heavy industry, our innovative, high-quality rolling mills are designed to enhance your production efficiency, product quality, and sustainability.

With decades of experience, The Steefo Group combines advanced technology with expert craftsmanship to deliver solutions that help you achieve optimal results. Our team works closely with you to understand your challenges and provides a rolling mill system that meets your exact specifications. From energy efficiency to precision and durability, our mills are built to elevate your operations and improve your bottom line.

Reach out to us at +91 87589 98607 or send us an email to marketing@thesteefogroup.com and let us show you how our customised rolling mill solutions can transform your manufacturing process. Together, we can build a stronger, more efficient future for your business.